What are the design approaches for a waterproofing system?

The approach to designing a waterproofing system involves carefully selecting the appropriate type of system to meet the unique needs and requirements of the structure it will protect. There are many different types of waterproofing systems available, each tailored to specific needs.

The approach will differ depending on the intended management of the water, whether it will be drained away as in the case of a shower or retained as in the case of a pool or a tanked basement wall.

When designing an area where water is intended to be drained away, elements such as steps, hobs, and surface falls are crucial considerations in the structural design details related to drainage. These elements must be treated as an integral part of the waterproofing system and included in the detailed design phase.

On the other hand, in the case of a water-retaining structural element such as a tanked basement, the waterproofing system will be continuously exposed to elements such as moisture and soil. Therefore, factors such as water chemistry, soil conditions and contamination must be taken into account when choosing the membrane type and detailing the membrane termination points.

What are the crucial factors to take into account when planning a waterproofing system design?

Well, waterproofing involves more than just applying a waterproofing membrane. A series of steps must be taken to guarantee that the water is drained out or retained effectively and without causing harm to nearby structures or the environment.

Here, we’ll take a brief look at some of the main considerations for waterproofing system design:

Environmental Conditions

A waterproofing system needs to be able to withstand the weather conditions it will be exposed to, such as extreme temperatures, wind, rain, or aggressive or contaminated soils. For instance, a plastic-modified fully bonded bituminous waterproof membrane known as APP (Atactic Polypropylene Plastic) is heat-resistant and is commonly used in hot climate zones such as Queensland. On the other hand, a rubber-modified fully bonded bituminous membrane known as SBS (Styrene Butadiene Styrene) is more suitable in regions such as New South Wales and Victoria.

Building & Area Properties

The detailing of a waterproofing system is dependent on various factors such as the type of building, the intended use of the area, and the location of the project. For instance, the wind exposure of the building can have an impact on the waterproofing detailing, requiring a higher membrane termination height on adjacent walls or vertical elements in a waterproofed area like on a balcony or roof when wind speed is high. Similarly, the porosity of the perimeter wall in a wet area will impact the type of flashing used.

Substrate Properties

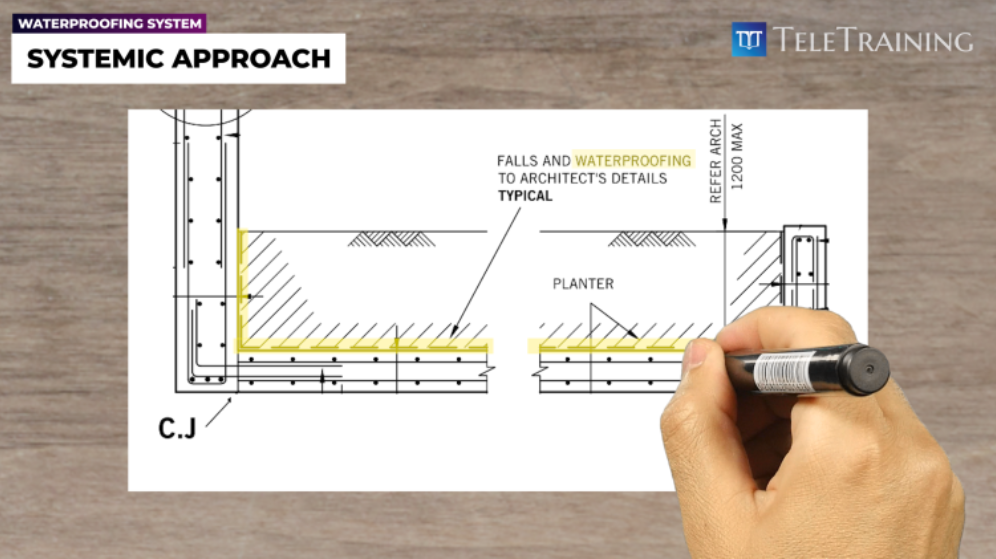

The surface or substrate that the waterproofing material will be applied to is a crucial factor that not only affects the choice of waterproofing material, but also the approach to preparation and installation. For example, a sharp corner, such as a wall-floor joint, can create local stresses in the membrane due to differential movement, potentially causing the membrane to tear at that point. To address this, fillets must be detailed at internal corners to provide a backing for the membrane and an unbonded length to accommodate any movement between the substrate and wall.

Surface Finish Properties

It is also important to consider the surface finish or material that will be applied on top of the waterproofing layer. In the case of a direct stick finish, it is essential to ensure that the adhesive or bonding compound is compatible with both the membrane and surface finish to avoid any issues.

For example, when the surface finish is ceramic tile that needs to be directly adhered on top of the waterproofing membrane, it is important to use a membrane that is compatible with the tile adhesive. Polyurethane membranes have a smooth and slippery surface with low adsorption capability, which may not be suitable for cement-based tile adhesives. In this case, it is better to use cementitious or water-based membranes.

What are some resources available for further learning?

As a leading training provider in the construction industry, we have recently released a course that provides builders & architects with a comprehensive understanding of the fundamental principles involved in designing a waterproofing system.

We have collaborated with a team of seasoned professionals, such as consultants, manufacturers, top-tier builders, and inspectors to develop this 3-hour online course. The course covers all the essential factors that need to be taken into account during the design and application of waterproofing systems.

Learn more about our Introduction to Waterproofing Systems course by visiting our website.

https://teletraining.com.au/courses/introduction-to-waterproofing-systems/

At TeleTraining, we pride ourselves on offering the most practical and hands-on training for professionals in the construction industry. Enhance your skills and knowledge by joining us and start producing higher-quality waterproofing work.